GENERAL

INFORMATION

|

DURADeckTM

and DuraGratTM Grating is

optimal in conditions where fire resistance,

low smoke and low toxic fumes are critical

concerns. It can stand up to the harshest

environments and provide years or service.

Each panel is produced in one solid

piece with no joints, which provides

maximum corrosion resistance, and bi-directional

strength. Non-flammability enables it

to withstand direct flame for an extended

time without sustaining major structural

damage. DURADeckTM Molded

Grating is as strong as Iso-Polyester

or Vinyl Ester Resin Grating but with

lower smoke and flame levels. |

What are

Phenolics?

GRP

Pipes and Rods using

Phenolics Resin |

Phenolics are in the same family of polyester,

vinyl ester and epoxy resins. They are

not new and have been used in major commercial

applications before unsaturated polyesters

became popular. Phenolics are composed

of phenol and formaldehyde. They are the

best organic material when it comes to

safety in the event of fire. Phenolics

have long been used in household items

such as toaster handles, wiring devices,

switch gears, pot and cutlery handles.

Features:

· Fire

Resistant

·

Low Smoke

·

Low Toxic Fume Emission

·

Ablative

·

Low Char Yield |

· Corrosion

Resistant

·

Light weight and easy to

install

·

Non-Slip Surface

·

Non-Conductive and Non–Magnetic

·

Impact Resistant |

|

Approval

for this product allows fiberglass grating

to replace steel which results in significant

savings in weight, ease of fabrication,

and installation. DURADeckTM and DuraGratTM

Grating can be used in offshore platforms

such as the following:

· Wave Zone Areas

· Wind Walls

· Mud Pits

· Preload Tanks

· Walkways

· Stairs

COMPARISON TO POLYESTER RESINS

We may achieve Class 1 flame spread ratings

(flame spread < 25) with halogenated

polyesters (resin with chlorine or bromine),

however, smoke density values for these

systems range from 500-800. Smoke generated

by halogenated resins is toxic and may

contain halogen acids, antimony oxide,

halides and oxyhalides, etc., all very

toxic. The only gases generated by combustion

of phenolics are carbon dioxide (CO2) with

trace amounts of carbon monoxide (CO) andsulphur

dioxide (SO2). No phenol or formaldehyde

was detected.

Phenolics have superior flame spread (< 10)

and superior smoke density value (< 10).

Oxygen index (ASTM D2863) for phenolics

(35% glass) is 45-80%.

Those concerned

about the potential health hazards

posed by phenol and formaldehyde

may rest assured that material

safety data sheets indicate that

the amounts of residual phenol

and formaldehyde in phenolics

are at low and very safe levels.

This is a valid concern since

our industry has spent millions

addressing styrene and toxicity

issues.

COLOR LIMITATION

Phenolics

are limited to a range

of light brown to black, whereas

most

phenolics are reddish brown,

dark brown or black. This

makes phenolic gel coats

impossible.

Using an epoxy or polyester

gel

coat will diminish the

phenolics flammability characteristics

slightly.

Source: James

E.

Maas, Director of Marketing

Reichhold

Chemicals

|

|

|

APPLICATIONS

The advanced resin and glass systems and

manufacturing techniques employed in the

production of DURADeckTM and DuraGratTM

GRP grating makes it ideal for use in the

following areas:

Industries:

· Offshore

· Mass

Transit

· Tunnels

· Mining

· Ship

decks

· Refineries |

Applications:

· Flooring

· Stairs

· Walkways

· Ramps

· Trench

Covers |

|

Select DURADeckTM and DuraGratTM GRP grating

and rest assured that you have a grating

that not only has a quality appearance,

but that is strong, providing a longer

service life over materials such as steel,

aluminum, and wood. By selecting DURADeckTM

and DuraGratTM GRP grating, you can rest

assured.

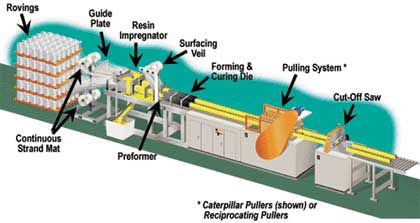

The Pultrusion Process

Pultrusion is a manufacturing process

for producing continuous lengths of reinforced

polymer structural shapes with constant

cross-sections. Raw materials are a liquid

resin mixture (containing resin, fillers

and specialized additives) and flexible

textile reinforcing fibers. The process

involves pulling these raw materials (rather

than pushing, as is the case in extrusion)

through a heated steel forming die using

a continuous pulling device. The reinforcement

materials are in continuous forms such

as rolls of fiberglass mat and doffs of

fiberglass roving. As the reinforcements

are saturated with the resin mixture ("wet-out")

in the resin bath and pulled through the

die, the gelation, or hardening, of the

resin is initiated by the heat from the

die and a rigid, cured profile is formed

that corresponds to the shape of the die.

While pultrusion machine design varies

with part geometry, the basic pultrusion

process concept is described in the following

schematic.

- The creels position the reinforcements

for subsequent feeding into the guides.

The reinforcement must be located properly

within the composite and this is the function

of the reinforcement guides.

- The resin bath saturates (wets out)

the reinforcement with a solution containing

the resin, fillers, pigment, and catalyst

plus any other additives required. The

interior of the resin bath is carefully

designed to optimize the wet-out of the

reinforcement.

- On exiting the resin bath, the composite

is in a flat sheet form. The pre-former

is an array of tooling which squeezes

away excess resin as the product is moving

forward

and gently shapes the materials prior

to entering the forming and curing die.

In

the forming and curing die, the thermosetting

reaction is heat activated (energy is

primarily supplied electrically) and

the composite

is cured (hardened).

- On exiting the die, it is necessary

to cool the hot part before it is gripped

by the pull blocks (made of durable urethane

foam) to prevent cracking and/or deformation

by the pull blocks. DURA® uses two

distinct pulling systems, one that is

a caterpillar counter-rotating type and

the

other a hand-over-hand reciprocating

type to pull the cured profile to the

saw for

cutting to length.

- In certain applications an RF (radio

frequency wave generator) unit is used

to preheat the composite before entering

the die. When in use, the RF heater

is positioned between the pre-former

and

the die.

|