|

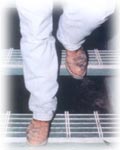

NON-SLIP

Fiberglass

Gratings integral grit top

surface provides outstanding

anti-slip protection for

personnel (in wet and oily

environments). The grit is

embedded in the top surface

of each panel prior to curing.

This combination of integral

construction, plus depth

of the embedded grit, creates

a long-lasting maximum anti-slip

top surface. |

|

|

FIRE

RESISTANCE

Fiberglass

Grating is available in various

resin systems, two of which

meet the Class 2 flame spread

rating, in accordance with

BS 476 Part 6 and Part 7. |

|

|

NON-MAGNETIC

The non-magnetic

properties allow the fiberglass

grating to be used in sensitive

installations where the inherent

magnetic properties of metallic

grating would prove unsuitable. |

|

|

IMPACT

RESISTANCE

The impact

resistance of Fiberglass

Grating allows repeated deflection

without permanent deformation.

A certain amount of deflection

can occur with loading. However,

once the load is removed,

the grating will return to

its original shape, unlike

metallic grating, which will

remain deformed and require

costly repairs or replacement.

Loading/deflection tables

are available on request. |

|

|

NON-SPARKING

The non

sparking qualities of Fiberglass

Grating systems are ideally

suited for those installations

where hydrogen or other combustible

gases may be found and which

may explode or cause a fire

from sparks produced from

accidental dropping of tools

onto the |

|

|

MAINTENANCE

FREE

The use

of Fiberglass Grating virtually

eliminates maintenance costs

since painting is not required,

and UV inhibitors protect

against degradation from

the sun. |

|

|

LIGHTWEIGHT

Fiberglass

Grating weighs about one-quarter

as much as steel grating.

Two men can easily handle

full panels, without the

need for hoists, pulleys

or dollies. If the Fiberglass

Grating needs to be moved

for cleaning, maintenance

or utility access, there

is less chance of back injuries.

The lightweight design of

the grating reduces installation

and fabrication costs, weighing

only 12 kilos per sq mtr

for 25mm and 18 kilos per

sq mtr for 38mm. |

|

|

RAISED

FLOORS

Many

plant operations have a need

for slightly elevated Floor

Grating. Fixed or adjustable

pedestals can be used for

applications up to a height

of 600mm. Plastic insert

mouldings, which raise the

Fiberglass Grating panels

7mm off the floor, are ideal

for allowing liquid drainage

below the Grating. |

|

|

DESIGN

The design

procedures associated with

Fiberglass Grating are entirely

different from those associated

with other materials. The

prime consideration in designing

with fiberglass is allowable ‘deflection’ as

opposed to ultimate ‘loading’ used

with steel and aluminium.

The reason for this is the

inherent elasticity of reinforced

plastic, permitting far greater

deflection than steel, without

the danger of structural

failure.Load and deflection

tables are available on request. |

|

|

COST

SAVINGS

In a

review of costs, Fiberglass

grating showed significant

savings over the use of stainless

steel grating, and when consideration

is given to ‘life cycle

costs’, combining anti-slip

benefits, the saving over

the use of metal grating

alternatives is quite considerable. |

|

|

NON-CONDUCTIVE

The non-conductive

properties make Fiberglass

Grating ideally suited for

work platforms and flooring

situated in electrically

hazardous locations. |

|

|

LOW INSTALLATION

COSTS

Fiberglass

Grating weighs considerably

less than conventional metal

gratings, and is easier and

less expensive to transport,

install and remove. Only

simple hand tools are required

for installation and removal,

eliminating the need for

costly equipment and labour

costs associated with heavy

lifting, cutting and welding. |

|

|

SUPERIOR

STRENGTH

The high

glass-to-resin ratio of fiberglass

grating provides superior

strength and load-bearing

characteristics. With structural

integrity protected by its

unique corrosion resistance

capabilities, fiberglass

grating lasts longer than

traditional materials. |

|

|

MECHANICAL

STRENGTH

Breaking

strength under a lateral

force is exceptional. The

uni-directional continuous

fiberglass reinforcement

offers numerous advantages,

including rigidity, shock-resistance

and no permanent deformation

after overloading. These

factors provide excellent

mechanical strength and a

generous factor of safety.

Fiberglass Grating is designed

for maximum safety in intensive

industrial use. |

|

|

HIGH

PERFORMANCE

Composite

structural fiberglass grating

materials have demonstrated

a proven ability to withstand

the harsh side effects of

corrosive conditions better

than galvanised steel. For

many years, composites have

been reliably used in traditionally

corrosive industries such

as chemical processing, plating

and marine construction.

While the cost of material

is an important criteria

in the design of a project,

it does not reflect the total

cost of the project. Beyond

material purchase price,

the engineer also should

consider the related costs

of installation, maintenance

over time and replacement

of debilitated materials.In

addition to improving safety

standards Fiberglass Grating

provides excellent chemical

resistance is easy to install

and offers long term durability.

The gritted anti-slip surface

has one of the highest degrees

of slip resistance ever measured

for a walking surface. Consideration

should be given to installing

Fiberglass Reinforced Plastics

Stair Treads, Fiberglass

Reinforced Plastics Gully

Covers, Glassfibre Reinforced

Plastics Stairs, Glassfibre

Reinforced Plastics Mini

Mesh, Glassfibre Reinforced

Mesh Grating, Glassfibre

Reinforced Plastics Steps,

Gratings, Grid, GRP, GRP

Anti Slip Grating, FRP Floors,

FRP Grating and FRP Stairs |

|

|

LONG

MAINTENANCE-FREE LIFE

DURA® product

cuts life cycle costs dramatically |